Laser welding services

Camtech Engineering are leading experts in laser welding in south east Queensland. We can manage small, intricately detailed jobs through to large-scale laser welding projects.

The low thermal distortion provided by laser welding makes it ideal for the repair of existing tooling and/or completing new tooling.

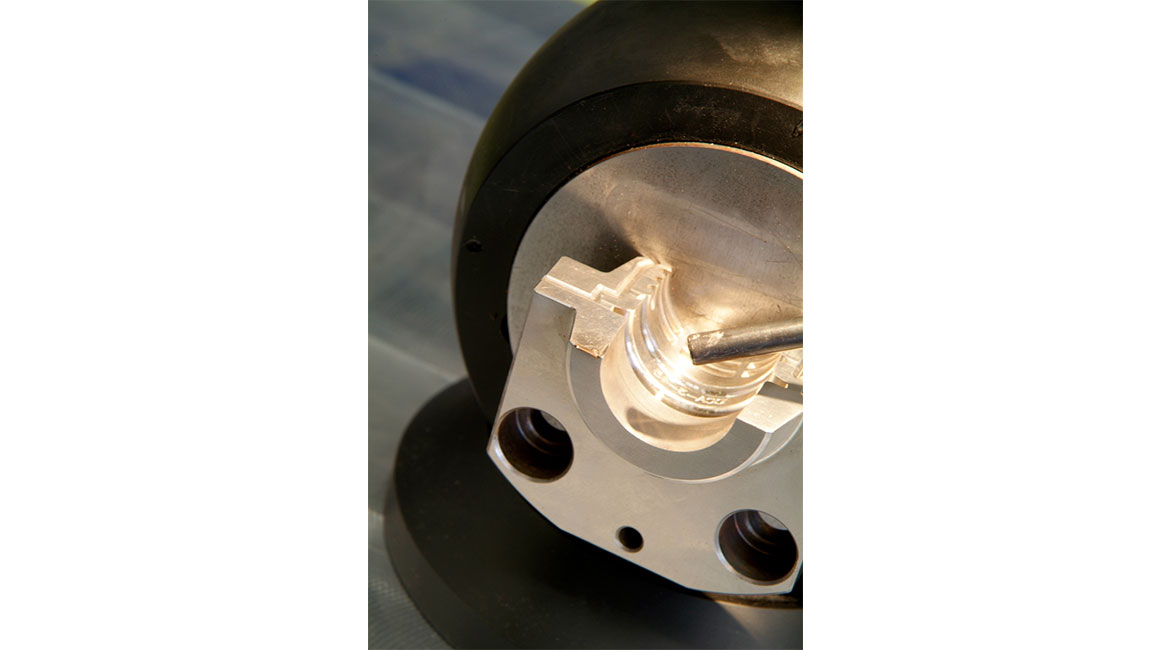

Repairing Existing Tooling

The precise approach of laser welding, with its low thermal distortion, allows for a seamless bond returning the part to ‘as new’ condition.

Cost Effectiveness

In many instances it is cost prohibitive to remake tooling. Laser welding is a cost effective, time efficient method of restoring damaged inserts.

Who Can Benefit from Laser Welding

Typically, our laser welding clients are in tooling industries and many are involved with plastic injection moulds, diecasting, and aerospace industries.

A common request we receive is to renumber yearly date stamps to upgrade the previous year number with the new year. This is done by filling in the old number with weld and engraving the new digits.

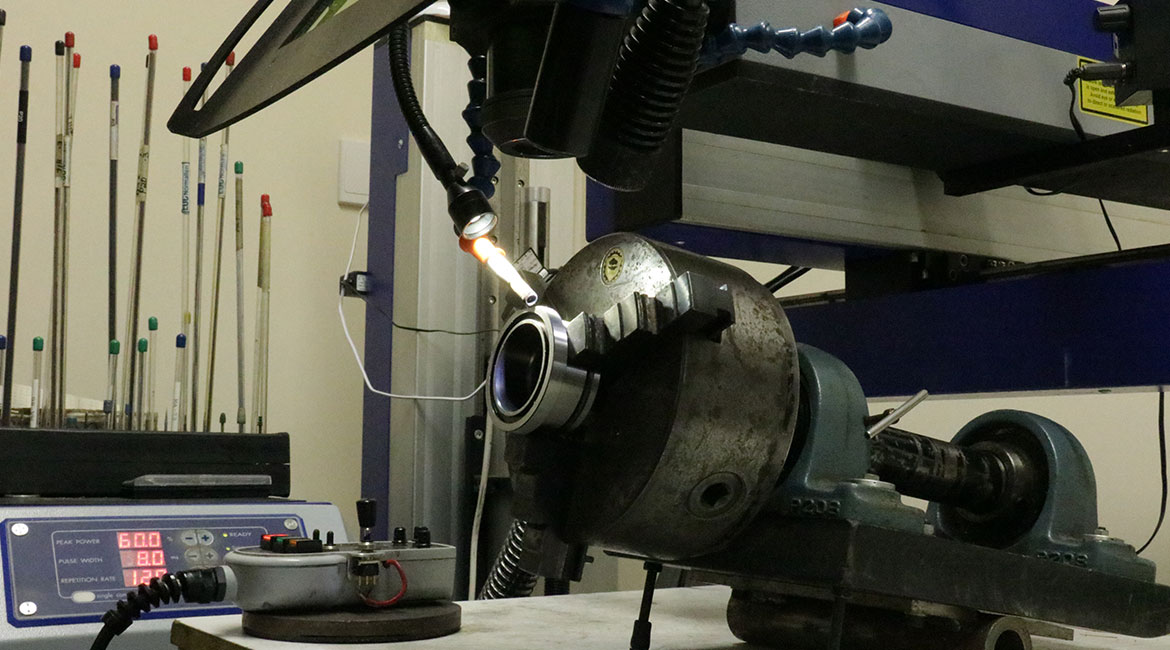

Our Equipment

We use a German designed and manufactured OR HTS150 Mobile Welder. Its standard features include:

- Autofocus system

- Motor traverse in X/Y/Z and R-axis

- Digital joystick

- Direct laser beam source

- High quality rail system by THK

Contact Camtech Engineering for all your laser welding needs Australia wide

Very few toolmakers have the capabilities to provide a professional laser welding service that can return a damaged item to its original shape and form in the virgin material.

Laser welding allows our clients to:

- Save money

- Replicate parts that are too costly to purchase or no longer available

- Modify an existing item or part