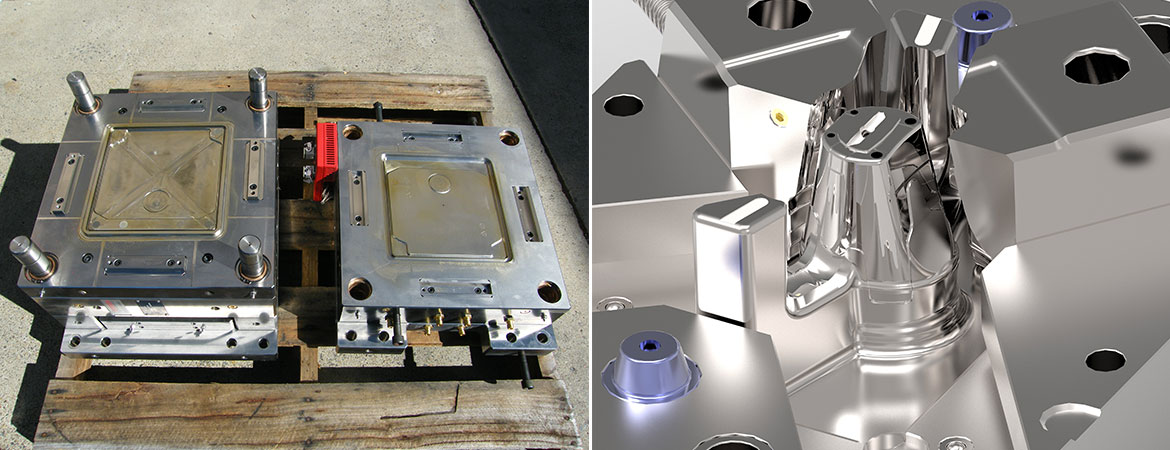

Injection moulds and precision engineering

Camtech Engineering have the facilities and expertise to manufacture single, family or multiple cavity injection moulds.

All our injection moulds are produced from stainless steel mould plates for corrosion resistance and easier mould maintenance.

Wherever possible our injection moulds have standard interchangeable components. It is our preference upon consultation with our customer, that cooling water is manifolded at the bottom of the mould, which can eliminate leaks that can leave a watermark on the finished component. Our injection moulds are ideal for plastic and packaging industries in sectors including health and medical, agriculture, automotive, appliance, and horticulture.

We have produced many overmoulding injection moulds, a process which combines two or more moulded plastic or rubber parts into a single finished product such as a baby teat, toothbrushes, etc. An overmoulding tool requires high precision and reliability. The base layer is moulded first, then the additional plastic layer(s) are molded over and around the original part. A common example of an overmoulding component is a toothbrush with a stiff frame and rubberized grips on the handle.

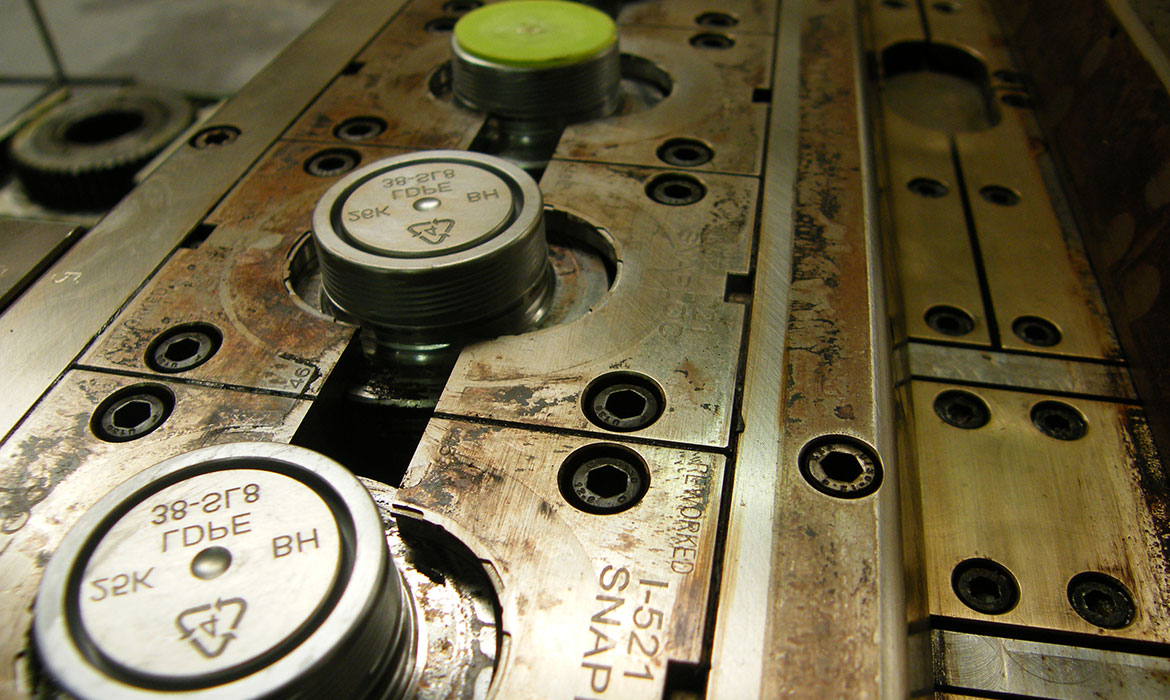

Closure Moulds

Camtech Engineering have a team of specialists with expertise in both mechanically unscrewing and strip-off closure injection moulds. We have the expertise and equipment to design and manufacture moulds for a variety of closures including screw caps, twist-off caps, and tamper evident closures.

Preform Moulds

We are the largest producer of multi cavity injection moulded preform tooling in Australia. Preform tooling is the first critical stage in producing PET bottles. A preform looks like a test tube with a fully formed precision neck finish and a tube of plastic hanging below. Preforms come in multiple sizes and weights depending on the bottle application.

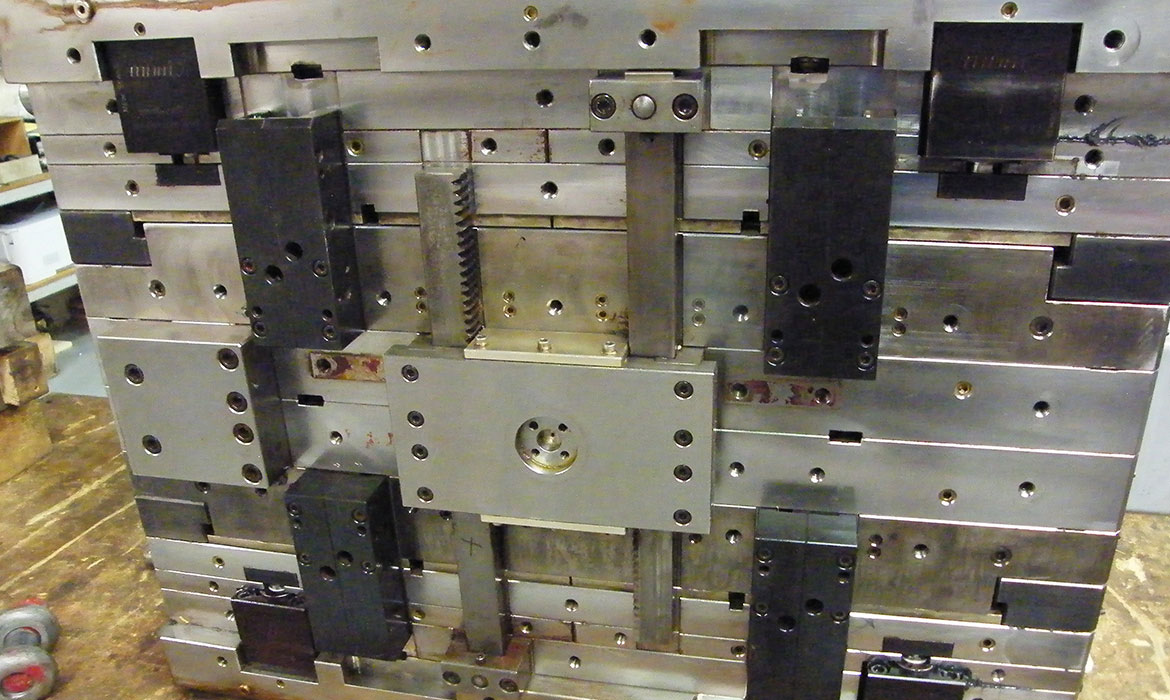

Stack Moulds

Camtech Engineering have highly-skilled specialists in multi cavitation stack moulds. We are Australia’s largest designer and manufacturer and have developed more than 25 unique stack moulds to meet the specialist needs of our clients.

Our suite of toolmaking and engineering services include, CAD, CAM, Reverse Engineering, Laser Welding, Laser Engraving, Deep Hole Drilling, Engineering Consultancy, and Onsite Consultancy.