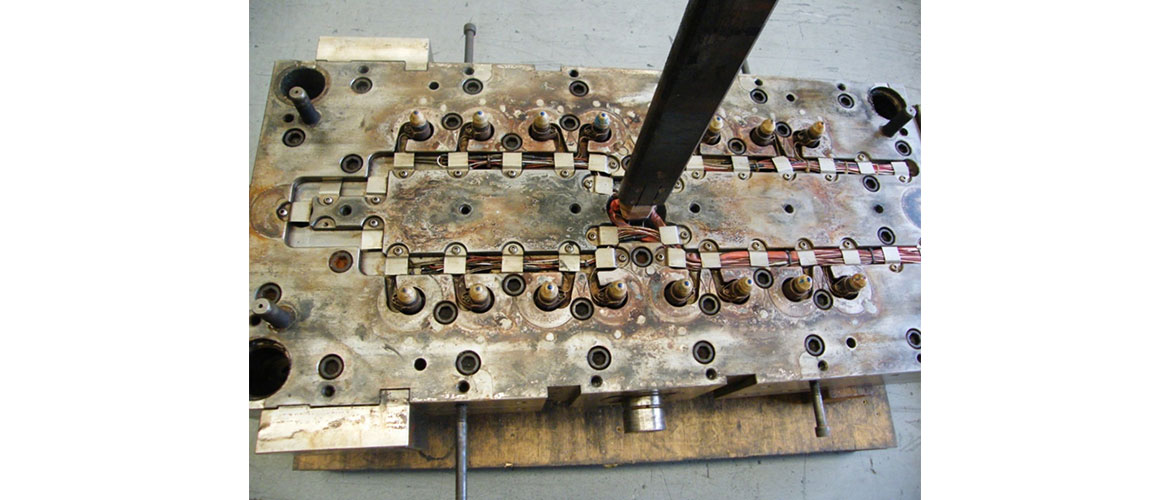

About our existing mould refurbishment service

Although it can affect production schedules to send a mould out for refurbishment, it is economically beneficial to produce a ‘just like new’ mould for a fraction of the cost of a new mould.

Refurbishment can consist of something as little as swapping out guide pins and bushes, to total replacement of all functional wearing items. Most of the costs for a new mould are in the steel plates. When refurbishing we only change the items required, to return the item back to an ‘as new’ condition.

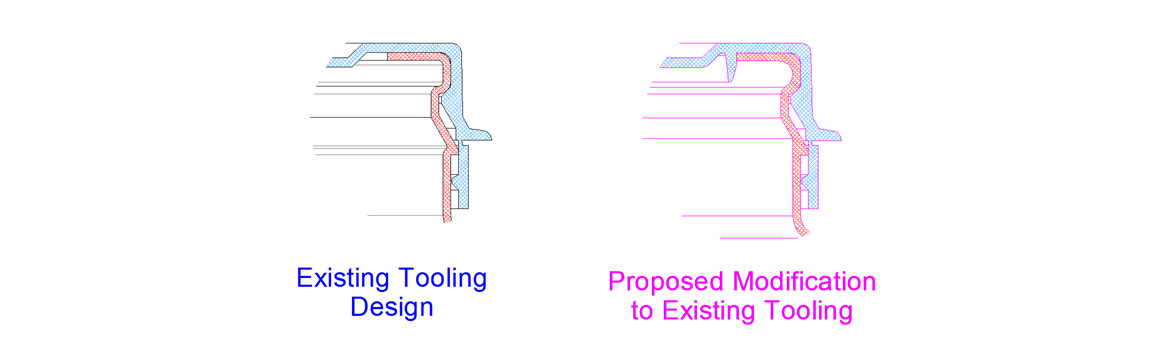

Modifying Existing Tooling

Modifying existing tooling is typically an economical way to create a new version of an existing product, to modify it, or adapt it to produce a en entirely new product. Costs are reduced because we can typically use the existing infrastructure of the tooling.

Our fully qualified team are experienced in all the diverse forms of tooling construction. This means that we can offer the most cost-effective method of upgrading your tooling requirements. Not only can we modify tooling that we have manufactured, we can reverse engineer tooling produced elsewhere, which allows you to upgrade your tooling requirements to the latest standards.

The benefits of refurbishing or modifying existing tooling

- Maintain the product quality throughout its production life cycle

- The ability to optimise and build upon your current tooling investment

- Extending the production life of your existing tooling

- Maximising your investment in existing tooling

Our on-site toolmaking facilities allow us to support all your tooling requirements. To speak with an expert in existing mould refurbishment, contact Camtech Engineering on the Gold Coast.