About our CAD and Solid Edge software

CAD (Computer Aided Design) software is used by our engineers to generate technical drawings which can replicate precision 3D models of any component we manufacture. CAD/CAM (Computer Aided Design/Computer Aided Manufacturing) is the integrated ability to use information from the concept design stage through to the completed manufactured object.

Solid Edge

At Camtech Engineering we use Solid Edge as our primary CAD software, which is a computer software product produced by Siemens PLM.

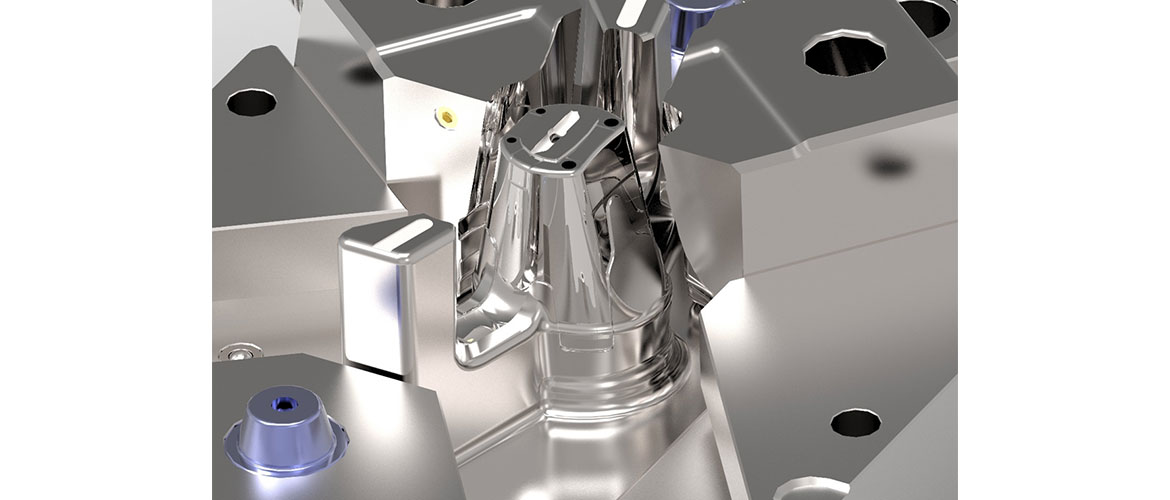

Using Solid Edge allows us to generate complex 3D models and assemblies of the tooling we produce. Using true 3D software allows us to explore various design parameters and optimise the final product.

How CAD can bring your designs to life

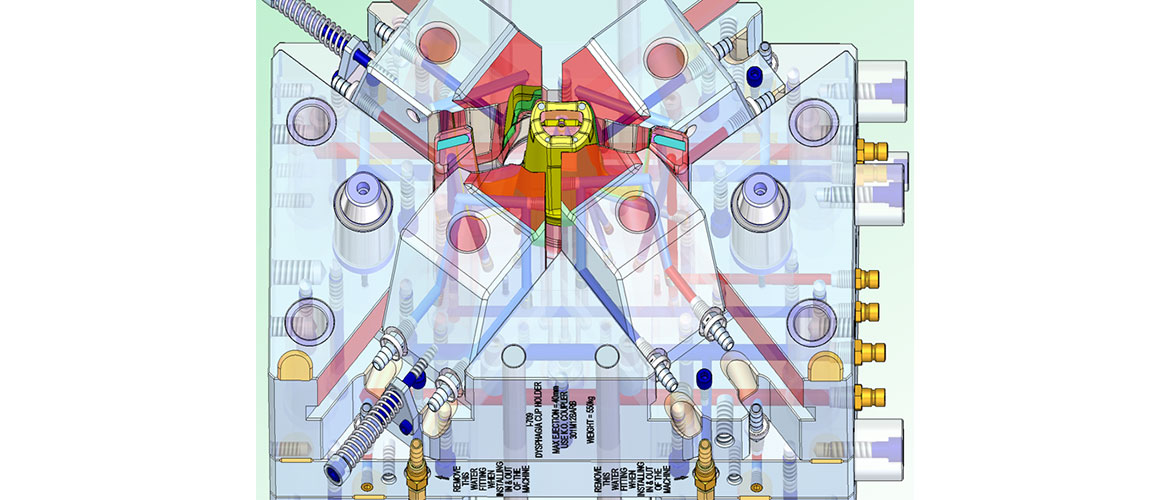

Being able to colour code, see through, and section our models, ensures that all our precision manufactured items fit together and function correctly the first time.

Product Design

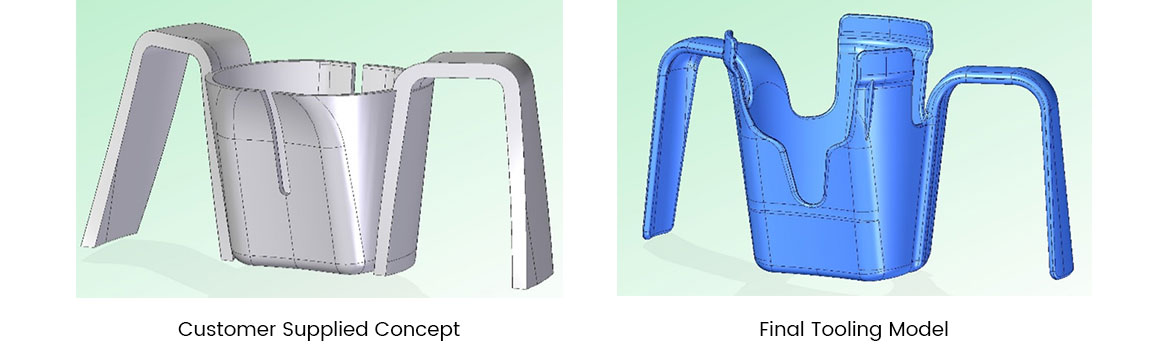

Product design has become an increasingly important part of our business at Camtech Engineering. Many of our clients no longer employ designers to produce their product, instead they supply us with a basic concept, and together we refine the item into their finished product.

Our clients specialise in many different fields and often don’t understand the complexities of product design or tool design. This is where the benefits from our experience can be used to refine a crude impractical design into a useable product. There is a great deal of skill and knowledge involved in producing a model of a free form object that can then be used for tooling.

Tool Design

Tool Design is a specialised area of manufacturing engineering which comprises many different fields. Fields include analysis, planning, design, construction, and function of the tool, along with considering the methods and procedures necessary to increase manufacturing productivity.

At Camtech Engineering tool designs are done in house by our highly experienced staff. All our tool designs incorporate best practice manufacturing principals as practiced in our manufacturing facility.