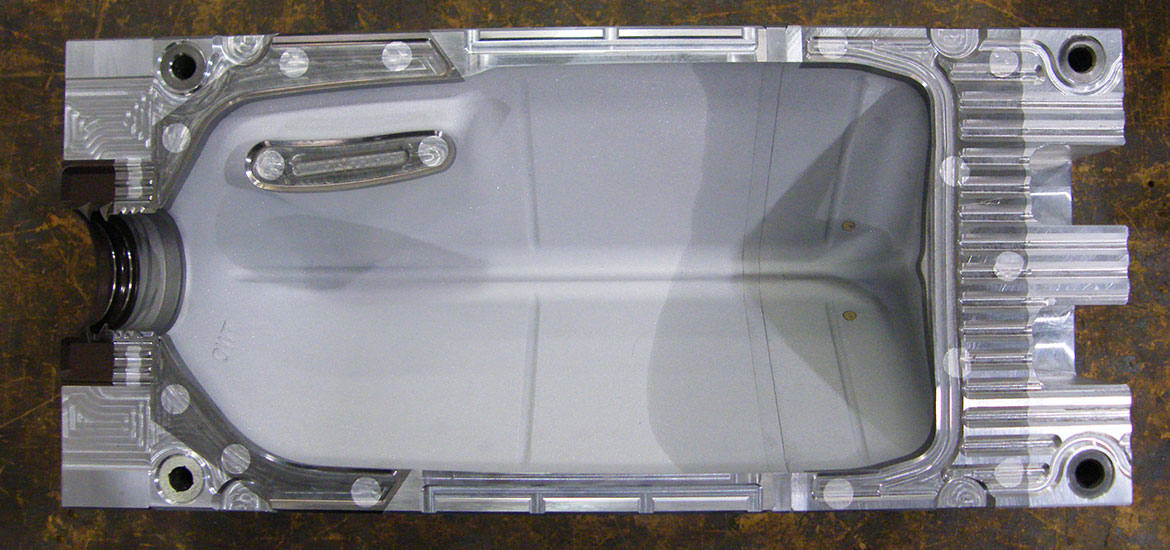

Extrusion Blow Moulds

Camtech Engineering are experts in the manufacture of Extrusion Blow Moulds to suit all Extrusion Blow Moulding (EBM) machines. We produce Blow Moulds from 80mL to 25 Litres. Depending on your application and the plastic resin being used, we can cater the construction to be aluminium or stainless steel. We are innovative in our approach to design and are continuously improving our products to enhance productivity, efficiency and effectiveness for our clients.

For one of our clients, we recently introduced an innovative new Air Cooled Blowpin Button that significantly helped to stabilise neck finish sizes in “Pull Up” or “Ram Down” applications. Camtech are at the forefront of producing stronger, lighter weight bottles for the marketplace. Stay tuned for our new 2 Litre Milk Bottle soon to hit the market.

A significant proportion of Camtech Engineering’s activity is involved in producing extrusion blow moulds for a wide range of dairy, food, bathroom, and laundry products for major Australian and international clients.

What is a Blow Mould?

Blow moulding is a manufacturing process that is used to produce hollow plastic parts.

HDPE (High Density Polyethylene) plastic bottles are typically bottles that you cannot see through clearly. They are used for packaging milk, water, detergents, oil, poison, etc. Unlike PET Moulds, HDPE Extruded bottles can produce a bottle with a handle such as a 2 and 3 litre Milk Bottles, 4 litre Motor Oil Bottles, etc.