Laser welding and precision engineering

Camtech Engineering are the Gold Coast experts in laser welding. We can manage small, intricately detailed jobs through to large-scale laser welding projects.

The low thermal distortion provided by laser welding makes it ideal for the repair of existing tooling and/or completing new tooling.

With the ever-increasing complexity of plastic injected parts, it has become necessary for new, innovative ways of manufacturing.

Laser Welding – New Tooling

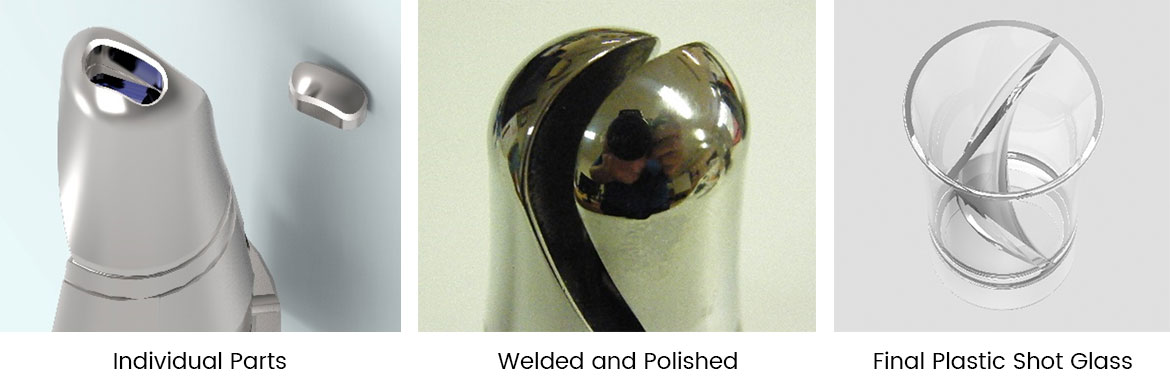

We were tasked with creating an Injection Mould for a ‘spiral shot glass’. The glass needed to allow storage of two separate alcohols so when opened and poured, allowed the mixing of the fluids.

Cooling the spiral shaft was very limiting until we revised how we were producing the cooling channels. To accomplish this, we milled a pocket in the head, allowing us to drill from both ends. We then manufactured an insert to fill the pocket and laser welded it in place.

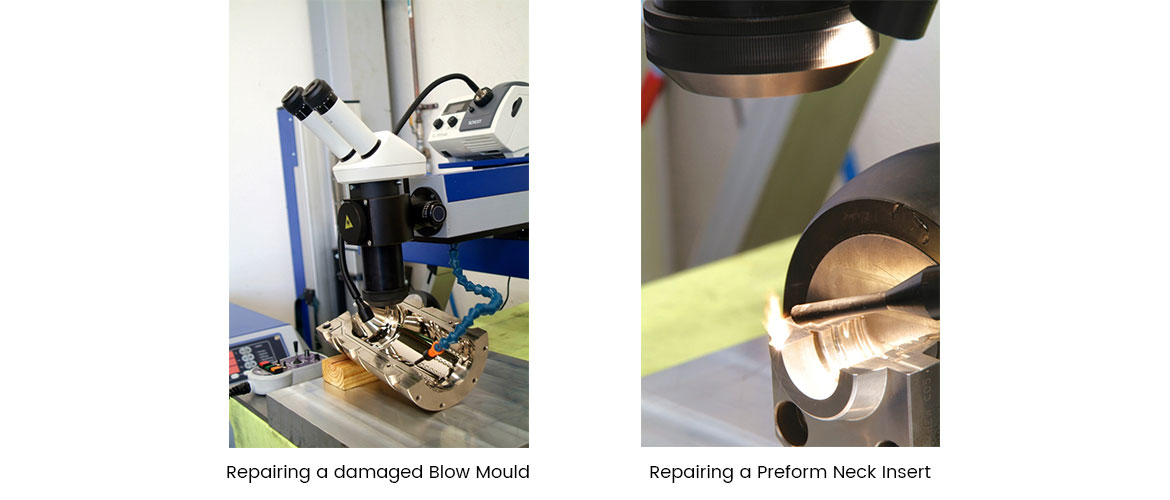

Laser Welding – Repairs

With the ever-increasing costs of tooling and the time it takes to manufacture new items, it is often cheaper and quicker to repair existing equipment.

With our state of the art, latest generation micro welder we can repair damaged items by bonding the virgin material into the damaged area and rebuilding the missing material.

Along with laser welding we also provide Laser Engraving as a service.

Our friendly team are always happy to chat with you about your laser welding requirements and provide you with a no obligation free quote. Our business hours are Monday to Thursday 7:00am until 5:00pm and Friday 7:00am until 4:00pm