Gold Coast CNC machining specialists

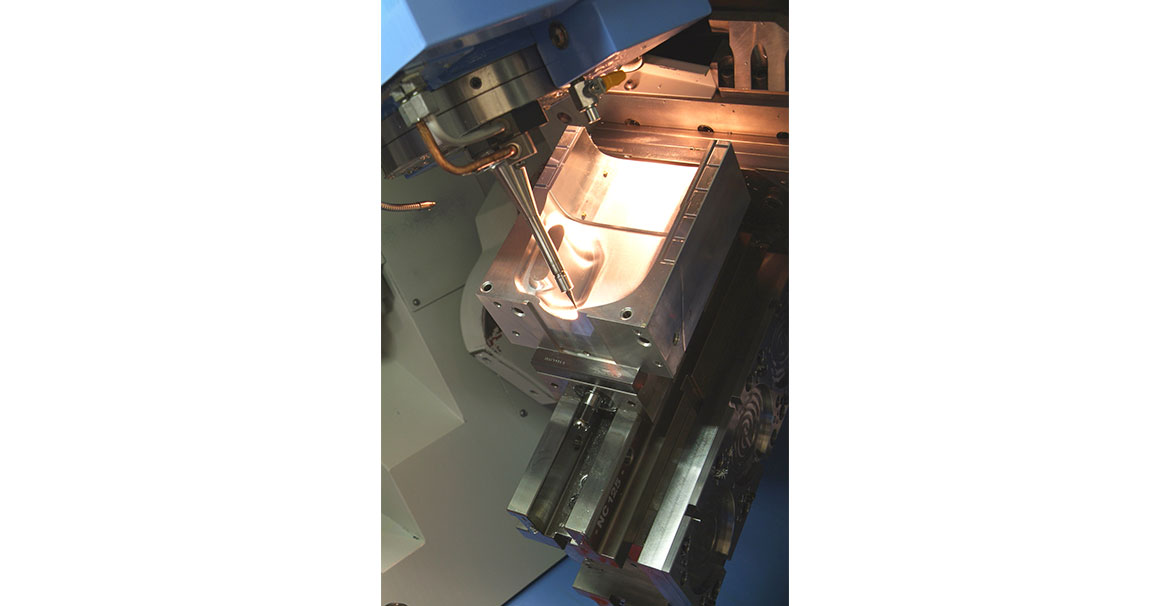

The advent of high speed machining is one of the major changes in the tool making industry in the past 15 years. At Camtech Engineering, we utilise the latest generation high speed Mazak machining centres (find out more by visiting page about our Equipment). The new Variaxis is ideally suited for more complex parts with the advantage of its five axis simultaneous movement.

The result is a faster and more accurate production process, through the elimination of multiple part set ups, reduced fixture costs and improved part quality. For increased versatility the Variaxis has been fitted with a two-pallet changer system. This technology contributes to Camtech maintaining its reputation as a leader in the field and for cost competitive on time deliveries.

We take pride in delivering:

- Cost competitive CNC machining

- Fast and accurate production process

- Latest high-speed Mazak machines (globally renowned machine manufacturers)

CNC Machining – Milling

At Camtech Engineering we have 7 CNC mills, three 5 axis Mazak machining centres and four 3 axis Mazak machining centres.

Our 3 axis machines have a maximum travel of 2000 x 1150 x 710mm and a spindle speed up to 12,000 RPM.

Of our 5 axis machines, 2 have pallet loading systems for extra versatility, and all have a maximum travel up to 630mm and spindle speeds up to 25,000 RPM.

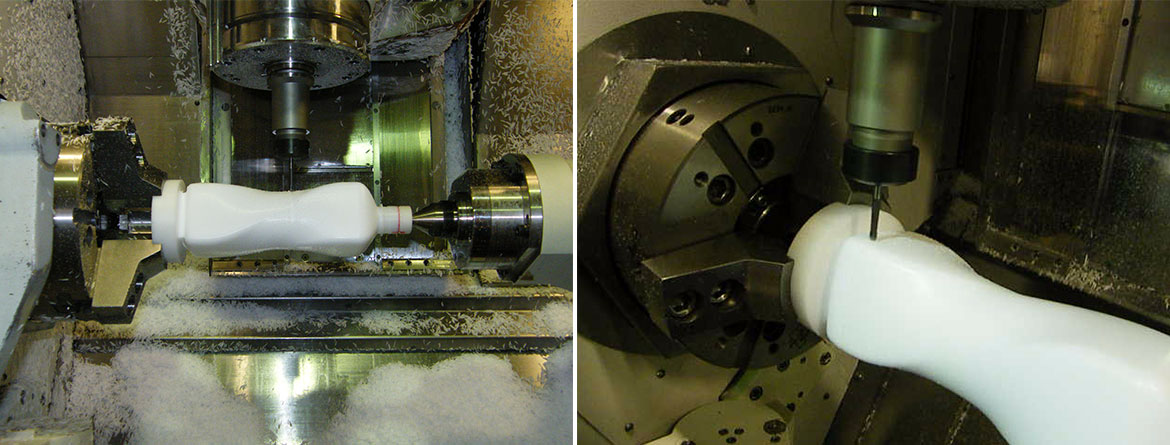

CNC Machining – Lathe

We have 6 CNC lathes, two 5 axis machines, one 4 axis machine, and three 3 axis machines.

All the lathes are equipped with live tooling with a maximum Mill Spindle Speed of 12,000 RPM and maximum swing of 550mm.

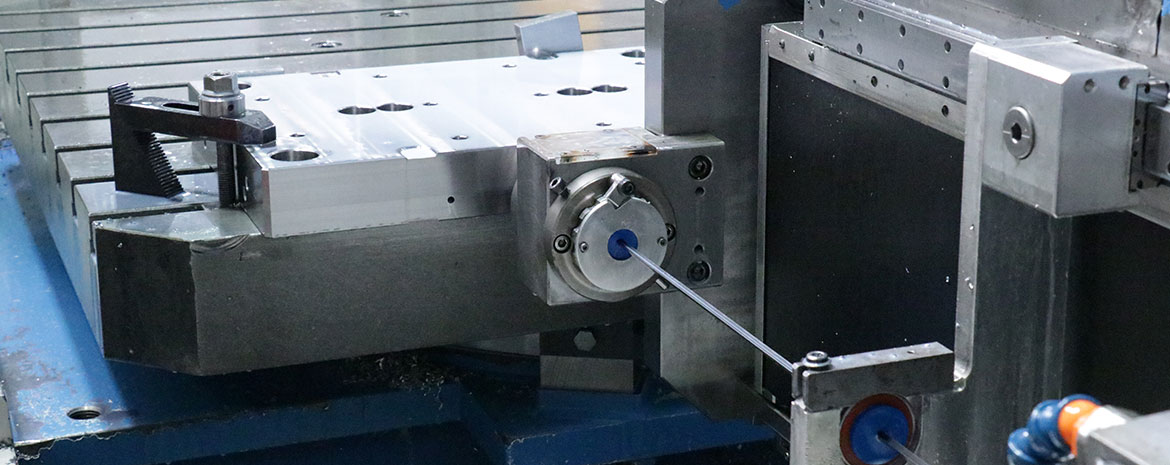

CNC Machining – Gun Drill

We have a 4 axis CNC Machining Centre Gun Drill capable drilling 1100mm deep with a maximum spindle speed of 6,000 RPM and travel of 1275 x 1600 x 1200.

CNC Machining – Cylindrical Grinding

We have two CNC Cylindrical Grinders with a maximum swing of 350mm x 1,000mm between centres.

Contact us for CNC Machining

If you’re looking for an engineering specialist in toolmaking contact our team at Camtech Engineering. Along with our precision engineering services, we offer an experienced and professional Engineering Consultancy for all kinds of projects, one-off or mass productions.